May, 2011

Standard Operating Procedures (SOP's) and specialty timbers

Verification

Both VSGVSG (Visual Stress Grades) are sorted on the basis of visual characteristics. Visual characteristics are good for determining strength but not so good for predicting stiffness. In the case of visual stress grades, the verification process is more pertinent for checking the stiffness characteristics. and MSGA machine stress grader is only capable of testing the stiffness of timber but not strength. There is correlation between stiffness and strength but visual characteristics such as knots are the main determinant of strength. Therefore visual grading is also undertaken after the wood has been machine graded for stiffness. In order to determine whether the strength properties for machine stress graded product are being achieved, samples of the production must be independently tested on a static testing machine in accordance with the Verification Standard NZS 3622:2004. This tests for both stiffness and also bending strength. grading systems assign timber into Structural Grades (SG) according to their stiffness and strength.

The key aspect to ensure both grading systems are compliant is the verification process. Both grading systems are subject to the same rules and grade acceptance criteria as set out in the Verification Standard NZS 3622:2004.

The verification process described in NZS 3622:2004 is an output control system, which means that timber is continuously taken from production and tested for stiffness and bending strength by the producer. Independent auditing also takes place. The Verification Standard is based on random sampling and statistical analysis to ensure the population of timber within a stress grade is meeting the requirements of the grade. Essentially, each grade has an average and minimum stiffness rating (Modulus of Elasticity).

Timber Grading

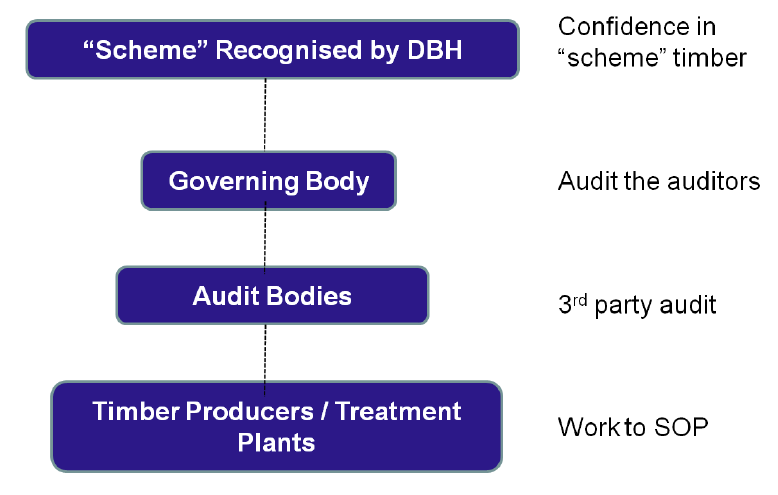

WPA, TIF & DBH have put together new “Standard Operating Procedures (SOPs)” for timber treatment and grading. The SOPs are part of a proposed new Timber Quality Scheme and set out requirements for all sawmills, plants & auditors producing structural timber in New Zealand.

The pilot scheme can be seen here and the Timber Grading SOP document is here

These procedures are suited for only larger operations producing radiata pine and Douglas fir and effectively shut out specialty timbers from the structural timber market.

NZFFA's respone to the Timber Grading SOP document, dated 17/5/2011 is here.

"The purpose of the SOPs is to give timber users, the public and the DBH confidence that timber used in houses has the same quality, no matter who is producing it. In other words, they can trust that it meets the branded hazard class and grade."

"The purpose of the Timber Quality Scheme is to implement and operate a system which provides assurance to timber users, the public (consumers) and the DBH that structural timber used in building and housing meets the required quality standards, is safe to use, fit for purpose and has been produced in a way that ensures the safety of people and the environment has been protected."