|

Farm Forestry Timbers |

|||

In this newsletter:

The draft Forest and Wood Processing Industry Transformation Plan has been released for public comment and I'm pretty happy that Central Government recognise the need to diversify our plantation forest industry along with the need for development of the market for products from alternative species, unencumbered by regulatory discrimination. There even seems to be recognition that the building code constrains utilisation of alternative species, something we have been lobbying on for years. Recognising the problems is one thing, but actually transforming NZ's wood industry and market is going to be a big challenge. There will be many decision points along the way, each of them critically important for our interests going forward. I trust that, as the only industry body representing the interests of local specialty timber producers, we will have a role in guiding officials along the way. Dean Satchell If you have a story for this newsletter, please get in touch with Dean by email. Progress in Australia with Engineered Wood Products Structural hardwoods have always been a good choice in Australia, with an abundance of natural forest eucalypts and other hardwoods. Their building code allows for a plethora of species and taking structural applications beyond solid sawn timber is a no-brainer. It's good to read about advances, and Australian Sustainable Hardwoods, based in Victoria, have been pushing their MASSLAM product hard in recent times. Its just good old fashioned glulam as far as I can tell, but I believe they have achieved scale efficiency. Some nice MASSLAM products are being produced, and they look good:

I also read in Timber & Forestry e-news (Issue 725) about another initiative being undertaken in Victoria to use spindleless lathe technology to test the potential to process smaller, lower-quality hardwood logs into LVL.

Producing engineered wood products from hardwoods should also be a no-brainer in New Zealand. I don't see any reasons why we shouldn't start producing structural hardwood glulam from locally-grown eucalypt here as a quality appearance product. We need to start thinking about what the products are that we can produce cost efficiently at a small scale. Maybe plywood and LVL can come later, but I'd suggest glulam is the lowest hanging fruit that doesn't require a large capital investment, nor scale to produce the goods. Can you think of other products in this category? I'd like to hear from you... Dean Satchell I'd love some feedback on this, but has covid dramatically increased the price of imported furniture? I was in Freedom checking out what is available and came across this Tazzie oak dining table for $3,000:

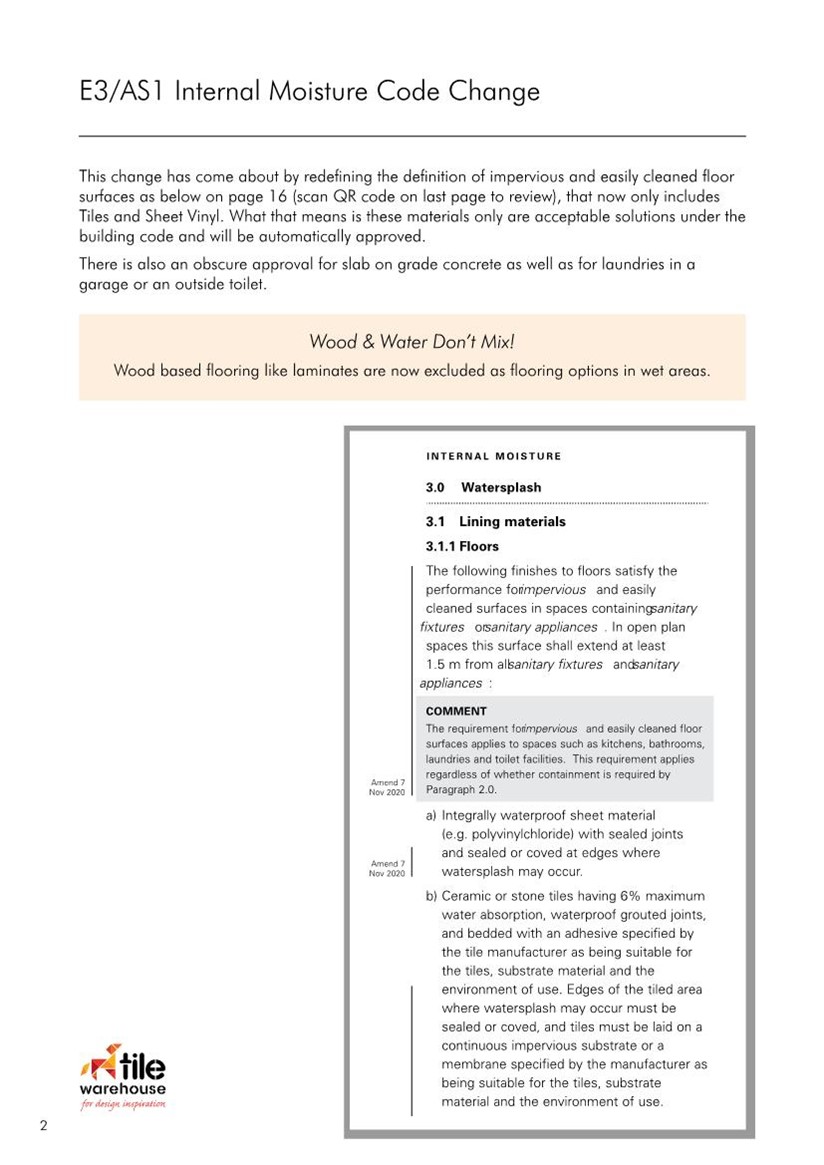

Yep, those grubby marks are skip... so not only is premium quality wood not required anymore, but at this price it would be pretty hard for a local manufacturer to say they can't compete with the price of imports! E3/AS1 Internal Moisture Building Code Change This from the tile warehouse website: The acceptable solution E3/AS1 for internal moisture regarding flooring in NZ, has changed from 5th November 2021. Timber-based flooring and a multitude of other options are no longer allowed (as an acceptable solution) in areas that are within 1.5 metres of sanitary fixtures or sanitary appliances. This description not only encompasses Bathrooms, Toilets and Laundries but now also Kitchens and some adjoining areas within 1.5 metres of fixtures and appliances. Now with only two acceptable solutions being tiles or stone over a fully compliant waterproof membrane or sheet vinyl, it is clear there is more focus on ensuring there is containment of water and protection of surrounding areas and adjoining tenancies. Alternative solutions can be proposed, however what is becoming more evident is that alternative solutions require a Council-approved waterproof membrane installed prior to any alternative flooring system. Councils are looking, or starting to look, at this as the start point.

From Frazer Brayshaw, Team laeader, Windsor Industries

I am looking for rough sawn timber (@ 2.4m x 150mm x 25mm) dry and ready for Furniture. Below is a list of the timber we use and amount use per year. If you can supply any of these timbers could you please let me know your prices Rimu (downgrade DB knotty) 14m3 Rimu (River) 6m3 Macrocarpa (Knotty) 7m3 Oak (American white) 4m3 Pine (Clear Grain) 4m3 Rimu (DA Colour) 2m3 Totara (Heart) 2m3 |

|||

Disclaimer: While every effort is made to ensure the accuracy of the information provided on this site, Farm Forestry Timbers Society do not accept liability for any consequences arising from reliance on the information published. If readers have any doubts about acting on any articles they should seek confirming, professional advice.

Farm Forestry New Zealand

Farm Forestry New Zealand