Farm-Totara

Farm-totaranamely; totara trees that have naturally regenerated on private land (particularly farmland and scrubland) following bush-felling, clearances and pastoral farming activity over the past 150 years or so. The term ‘farm-totara’ is intended to distinguish the subject from larger and older trees in old-growth forest remnants. Inevitably, there are occasional instances where large trees on farms may be remnants from natural forests. Nevertheless, despite some overlap, it is hoped that the term ‘farm-totara’ is a satisfactory short-hand for the younger naturally regenerated (or planted) trees that have more often established in disturbed and modified environments. timber from relatively young naturally regenerated totara trees of farmland is an excellent native softwood timber. Relatively easy to mill, dry, work and finish, it is suitable for all interior uses, particularly feature linings, joinery and furniture.

Farm-totara comes from sustainably managed New Zealand indigenous forests and farms. The Forests Amendment Act covers naturally regenerated totara trees on farms. Development of an industry based on the commercial-scale use of this native timber tree is seen as a practical way to encourage the integration and management of the regeneration on private land within existing largely pastoral land use.

Initiatives to promote farm-totara use along with the development of a sustainable commercial industry around it are underway. Constraints have been identified related to supply-chain issues, marketing and information gaps. A SFF funded Northland Totara Working Group survey (pdf 3.3mb, 2011) provides respondents views and insights into the direction of further research, and is the basis of the following information (see disclaimerDisclaimer: The results of this survey project set out within the body, summary and conclusions of this report (or any further dissemination formats), are intended to be available as public information for all stakeholders and interested parties. However, no guarantee as to truth, accuracy or validity of any of the results, comments, implications, recommendations, findings or conclusions are made by the author or by the Northland Totara Working Group or any other party. Users of any of the information, whether contained or inferred, in or arising from this report do so at their own risk. No liability or responsibility will be accepted.).

Product Qualities

Low shrinkage, excellent stability and workability;

Appearance and visual appeal.

| Properties | Heartwood | Sapwood |

|---|---|---|

| Basic density | 480 kg/m3 | 477 kg/m3 |

| Tangental shrinkage | 3.1% | 3.1% |

| Radial shrinkage | 2% | 1.4% |

Uses and Applications

See Showcase

Heartwood farm-totara

The high value of clear totara heartwood for exterior joinery is a traditional use that is still considered to be the main market for this grade.

Totara heartwood is recommended for exterior situations where durability is an important issue. In particular, exterior joinery such as doors and windows has been a main use. However, it has also been used for outdoor furniture, indoor furniture and cabinetry, veneer panels, framing, posts and beams.

Coloured and sapwood farm-totara

Coloured and sapwood totara timber grades are mostly used for interior applications, particularly joinery, linings, finishings and furniture. Treated sapwood could be used for exterior cladding and joinery, decking, fence battens and rails, and structural uses*Structural applications for totara under the building code currently require alternative solutions. Click here for more....

Niche applications

Niche markets for farm-totara include boat building joinery“It is lighter than kauri and holds a sharp edge. Some boat-builders prefer it for some applications.”, posts and rails in cattle-yards, gates, fence battens, house framing*Structural applications for totara under the building code currently require alternative solutions. Click here for more..., weatherboards, lintels*Structural applications for totara under the building code currently require alternative solutions. Click here for more..., decking, interior posts (in natural log rounds)*Structural applications for totara under the building code currently require alternative solutions. Click here for more..., log-house

‘Metal-X’ timber preservative has been applied to the finished surface of the otherwise untreated natural round totara logs of the log house. A timber preservative stain has been applied to the otherwise untreated veranda post. construction, joinery, ceiling linings, sarking, panelling, sills, architraves, mouldings, skirtings, flooring, doors, door-jams, window-frames, kitchens, bathroom vanities, furniture items, shelving, plywood veneer, coffin lids, souvenirs, wood-turning and carving

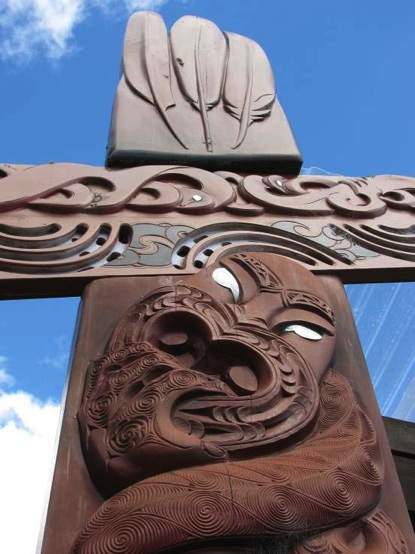

Peter Griffiths starts on the top section of a Pou for Kaitaia’s Te Ahu Centre..

Physical and Mechanical Properties

Farm-totara is considered to be a very good timber to work

Anthony Collins chisels a coloured piece of totara for a window sill. . It machines very well and with good dimensional stability. Gluing timber is not a significant issue. Some problems have been experienced with applied finishes to totara timber, particularly the heartwood. However, a range of satisfactory finishing products and procedures exist.

Working and finishing totara timber

- Farm-totara timber is considered to machineFarm-totara timber is considered to be a very good timber to work. It cuts and machines very well. Its workability is often compared to C. macrocarpa and kauri. “Doesn’t fluff-up with working or chip-out – on top for working against the grain- finishes well”; “Doesn’t chip-out much, good to finish” “More workable than just about anything” very well;

- Totara sapwood is considered to bend wellTotara sapwood bends very well. It has resilience (returns to original shape) and when bent it is very predictable, forming an even and consistent curve.;

- Finishes have been successfullyWhat finishes have been successfully applied? Finishes which have successfully been applied include: Totara primer; Taubman’s acrylic primer; “Any finish once sealed first”;“For oiled finishes always seal first with ‘EstaSeal SU 45’”; "Ure-clear – Wattle industrial grade polyurethane"; lacquer; lacquer/sealer; oil; two-pot polyurethanes; “use MDF sealer”; Danish oil; “Oil finishes – no problems”; waxed, water-based polyurethanes (such as Wattyl ‘Speed-Clear’) although can be blotchy with oil of heartwood; Tung-oil and Turps with 10% polyurethane in mix; ‘Liquid-glass’ two-pot polymer very effective; Shellac; Mix: (1/3 varnish, 1/3 turps, 1/3 tung oil); Norski resin on sealed timber (hardens the timber). applied to totara. Difficulties with finishes due to ‘oils’ in the heartwood and some movement of timber, especially from younger trees have been experienced. Some finishes have been found to be unsuccessful"Polyurethane takes about 3 weeks to dry on heart-totara"; "Most [single-pot] turpentine or oil-based Polyurethanes won’t set”; “Vegetable oil on a kitchen bench developed unsightly black water-stains”; Two-pot polyurethanes on totara heartwood; ‘Cabbot’s & Sikkens’ exterior oil & clear finish paint; Can get mould under oil finish; Oil based paints. . Nevertheless, respondents have generally found satisfactory finishing products/procedures and methods“Must be sealed with right sealer first – (use rimu sealer).” “Many polyurethanes wont set and some oils wont set. Polyurethane varnishes don’t seem to be a problem.” Mould or blooms under finishes are likely to be the result of moisture movement within the timber. Thorough drying is essential. . There are some inconsistencies with the above experiences and obtaining reliable advice from people with proven experiences is recommended.;

- Can split“Pre-drill holes!”; “Need to be careful with splitting”; “Harder to nail than pine.” .

- Can be difficult to glueProblems have traditionally been associated with totara heartwood. One respondent advised to wipe heart-totara with a solvent (like acetone) to remove greasiness before gluing. There are contradictory experiences regarding the success of Aliphatic glues (PVA family). One respondent warned that they discolour to a blue stain colour. One felt that the timber was not properly dry and, therefore, the glue was unsuccessful. Gorilla glue was listed as successful by most respondents.. Only 3 out of 33 respondents had experienced problems gluing totara timber. Therefore, it seems that the problem issues historically associated with gluing totara heartwood may no longer be a significant issue. Presumably, modern gluesRespondents have successfully used the following glues: Epoxy (Altex 421), Epoxy resin, ‘Bond-it-on’ by Holdfast, Water-based glues, Aliphatic resins (PVA family), ‘Gorilla-glue’, ‘resourcinol’, M-7 melamine glue for finger-jointing, Gelatine glue (Sheppy & Davis Grippet brands), Urethanes, "‘West system’ is best, wipe methylated spirits on each surface first", ‘Norski-resin’, polyurethane glues. and lesser heartwood content of the timber are the relevant factors.

The incidence of defects and issues appears to be relatively minor, and these do not create a significant disincentive around the use of regenerated-totara timber. Dimensional stability of totara timber from regenerated trees is excellent, although less consistent than old-growth totara timber.

Carving

Totara was and still is revered by Maori as being the best of all timbers to carve.

Carvers prefer well-seasoned heartwood from old-growth trees, but consider farm-totara to be a very good timber for carving.“Older dry heartwood is better to carve and has better colour.” “Younger wood often doesn’t finish as shiny as the old heart [when carved].” “Grain can lift on sapwood when sanding carvings.”

Availability

Search for farm-totara in the marketplace.

Most timber merchants, cabinet-makers, carvers and architects have indicated an interest in purchasing farm-totara if a reliable supply and continuity of suitable grades was available.

200x50 is the most popular nominal dimension, followed by 150x50 and then 50mm slabs.

Heartwood timber qualities of younger farm-grown totara trees vary from older-growth trees. Colour is the main distinguishing characteristic. The older and darker heartwood is generally considered to be more durable. However older-growth clear heartwood can have a bland appearance. “Sap and transition wood give character".

The characteristics of the bulk of the regenerating totara resource comprise mostly Feature, Coloured and Sapwood grades.

Natural Durability

Heart totara timber from old-growth trees

Totara heartwood from old-growth trees is extremely durable (Class 1, the highest class/category). This older and darker heartwood is generally considered to be more durable, more ‘oily’ than lighter coloured heartwood or transition-wood from younger trees.

Heart totara timber from regenerated trees

Opinions vary on how durable the lighter ‘pinky’ heartwood (or transition wood) is from younger totara trees. Most consider it has some level of natural durability but less than deep dark red heartwood from old-growth trees. Testing of natural durability levels of lighter-coloured ‘pinky’ heartwood from younger trees may be useful to determine suitability of the timber for above-ground exterior uses.

Sapwood, external uses

Anecdotal evidence indicates totara sapwood to be relatively more durable

Stockyard gates made by John Guy from totara milled off the farm and nearly 20 years old. Note the diagonal cross-brace board has been cut out to the wane (round edge of the natural tree). Therefore, it will certainly comprise a portion of sapwood. The gates received an application of diesel and waste oil approximately 18 months after construction. The gate is still in functional service, However, some rot is now evident where moisture is trapped at the bottom of the cross-brace board where it is fixed at the strap hinge and held against other boards. than most other sapwood timbers and to be much more resistant to the common house borer. Totara sapwood has also been used for exterior above ground situations. Sawn-timber has sometimes provided reasonable service-life, suggesting that it may have some greater level of durability than most other sapwood timber. However, despite these experiences, the untreated timber should not be considered sufficiently durable for exterior applications exposed to the weather. Totara sapwood can be very successfully treated with CCA treatment

Richard Davies-Colley shows gates made from tanalised sapwood totara wood that was milled from the farm. These gates are over 40 years and he says they are much stronger than pine. for exposed outdoor situations.

Sapwood, internal uses

Most people who have used totara sapwood for interior situations have used it as untreated timber and have not experienced any kind of durability issues. Anecdotal evidence suggests that totara sapwood is relatively more durable than most other sapwood timbers and to be much more resistant to the common house borer. However, totara sapwood should not be considered to be durable. Best practice techniques such as using dry timber, sealing it well and keeping it dry is still recommended.

Treating totara sapwood for exterior use

Experience is that LOSP or CCA methods are successful, particularly CCA on totara sapwood

Richard Davies-Colley shows gates made from tanalised sapwood totara wood that was milled from the farm. These gates are over 40 years and he says they are much stronger than pine. : “Sapwood gets better penetration than pine. Result is very good and durable.” Experiences with LOSP treatment of totara sapwood are presumed successful by the treatment plant rather than documented: “No one has come back and complained – so I presume it was fine”; “LOSP successful but expensive.” LOSP is an envelope treatment and, therefore, timber should be treated only once profiled and cut ends treated with an applied preservative.

Surface preservative finishes on totara sapwood for exterior use

Products such as Copper-napthylate, “Metalex”, Oils (deck & furniture oil, Danish oil, Tung oil mixed with turpentine and 10% volume of polyurethane, CD-50, acrylic paints, varnish, Diesel and creosote, waste-oil have all been used and appear to have assisted in ensuring a reasonable service-life has been experienced in exterior settings. However, oil finishes for items exposed to moisture may get a black discolouration

Coloured-grade farm-totara used for exterior joinery is showing some surface checking and the oil finish is getting a slight blackish discolouration..

Showcase

Disclaimer: While every effort is made to ensure the accuracy of the information provided on this site, Farm Forestry Timbers Society do not accept liability for any consequences arising from reliance on the information published. If readers have any doubts about acting on any articles they should seek confirming, professional advice.

Farm Forestry New Zealand

Farm Forestry New Zealand Farm Forestry Timbers - Headlines

Farm Forestry Timbers - Headlines