Kawa poplar timber - properties and market opportunities

Report Date: August 2023

Author: Dean Satchell, Northland Regional Council

Kawa Poplar Cabin - construction photographs and methods

H1.2 Radiata pine framing is pink. All other framing, joists etc are H1.2 boron treated Kawa poplar

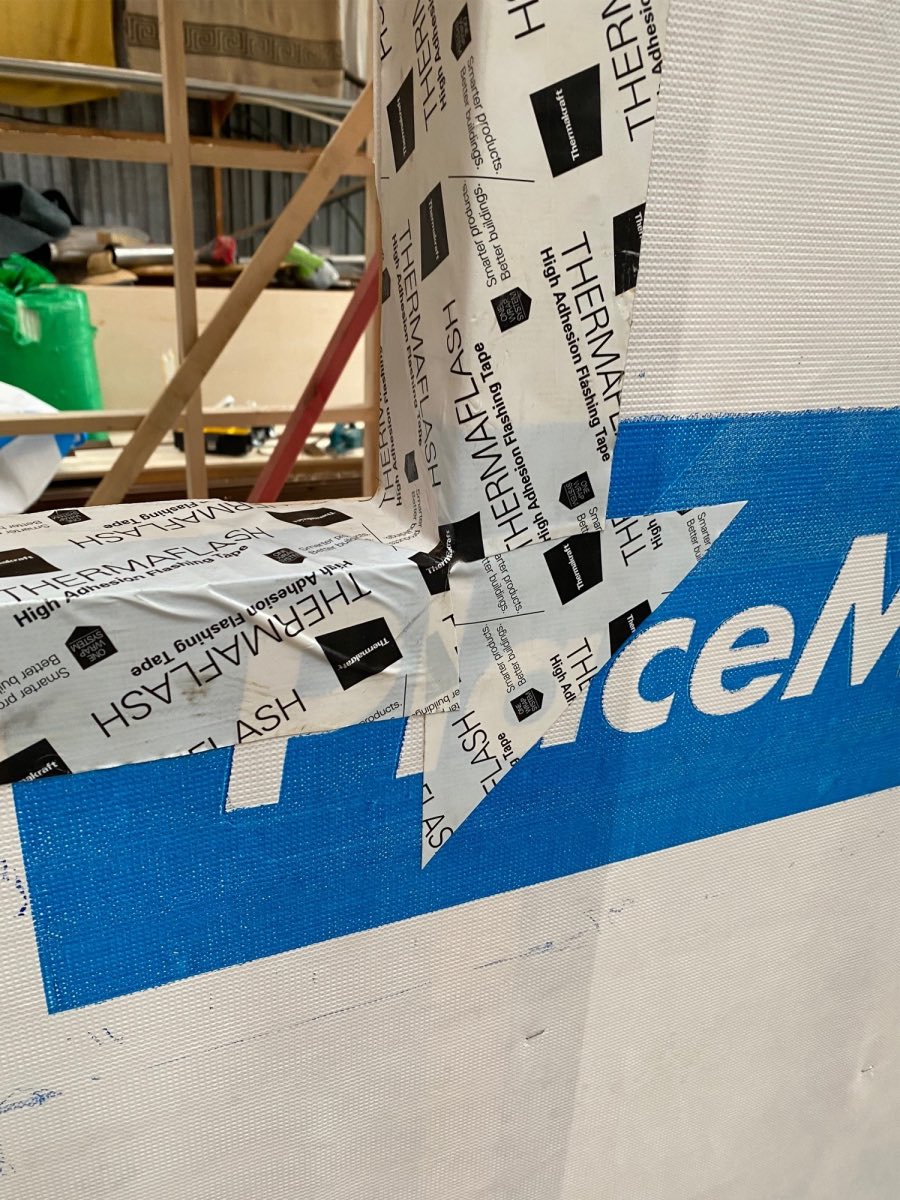

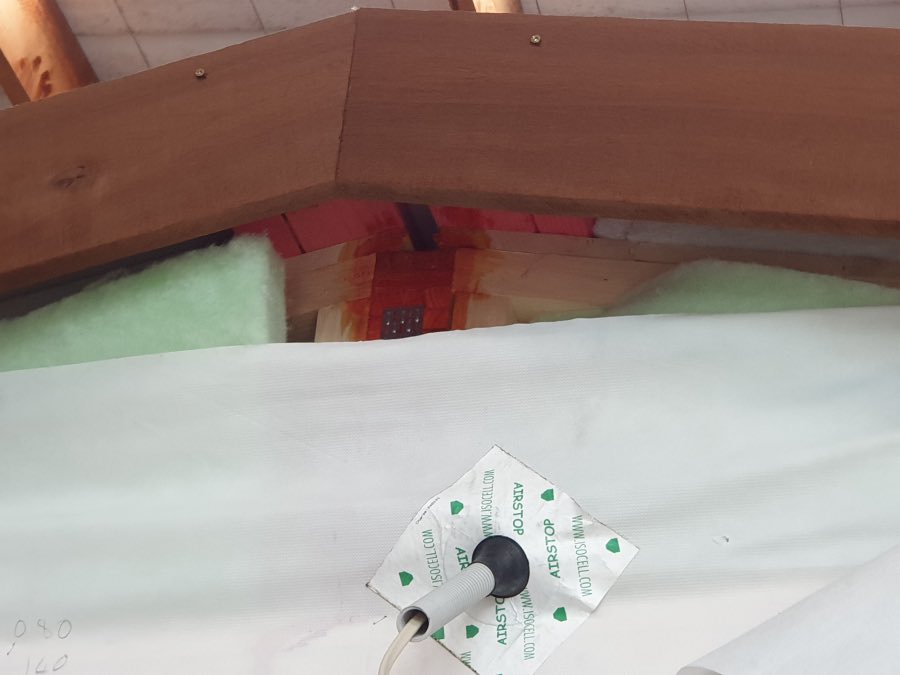

Kawa poplar sarking installed

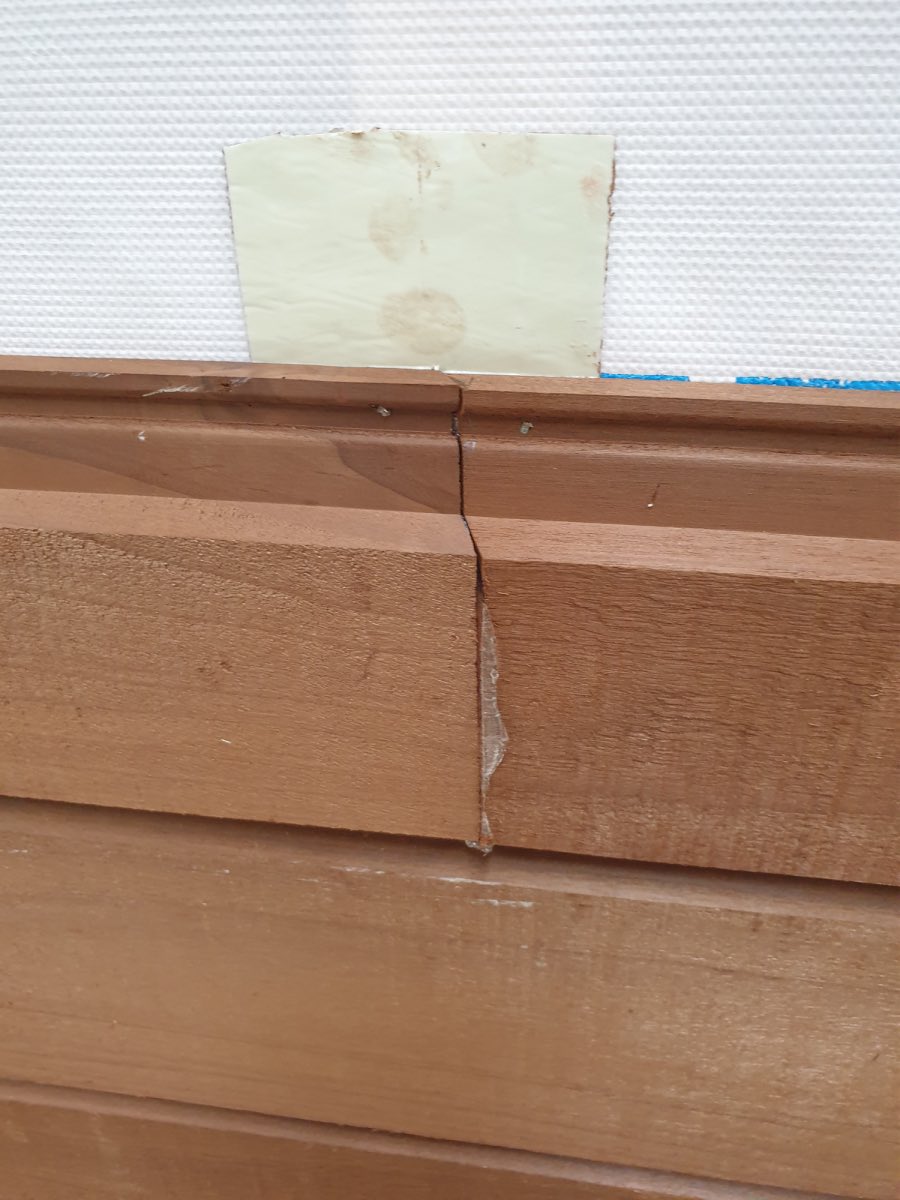

Sika modified silicon (MS) used for sealing weatherboard joins

End of laminated beam coated with TimTech BAX (88% boron)

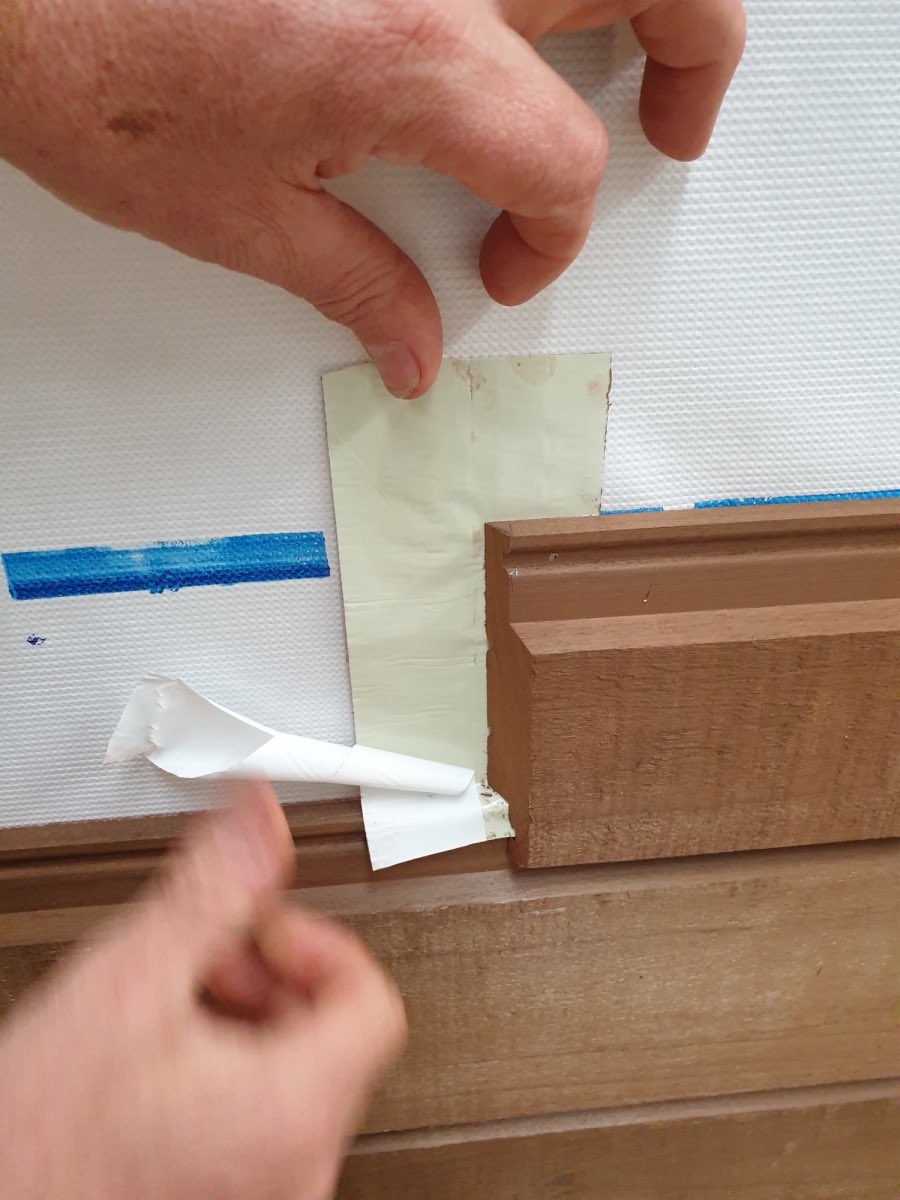

Voids and knot checks filled with Sika modified silicon (MS). Because these weatherboards were filled in final shape and form, surplus modified silicon was wiped off with methylated spirits.

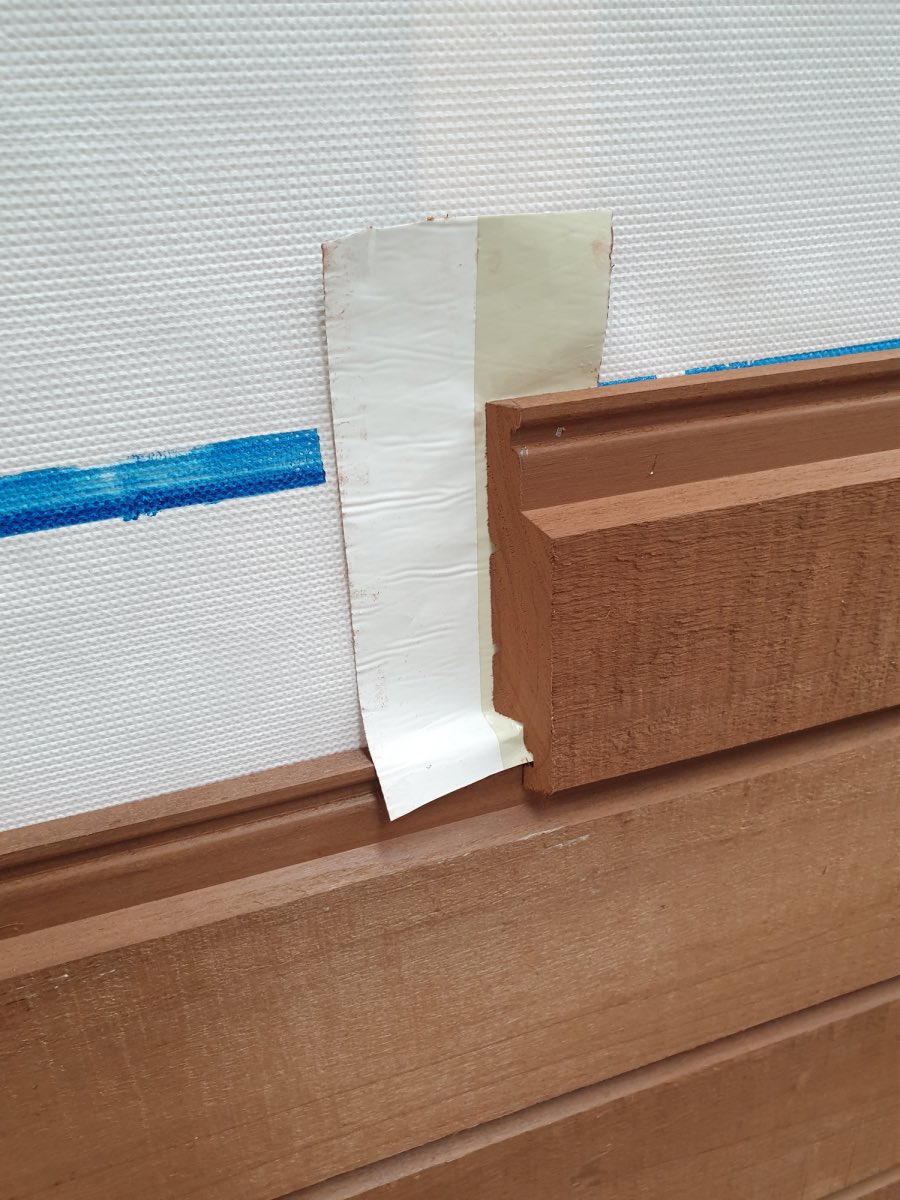

One H3.2 MCA treated Kawa poplar weatherboard (pale) is on each of all four sides of the cabin.

Flooring being installed over joists and polystyrene insulation.

Knot check filled with Sika modified silicon

Sika modified silicon (MS) used for sealing corner boxes.

Corner boxes with Sika modified silicon (MS) used to prevent water infiltration.

Installed floor

Floor, coated with epoxy then water-based polyurethane

Solid timber Kawa floor

Finished cabin ready for transport to NRC's Mata poplar nursery, 2nd August 2022

Poplar cabin at NRC Mata poplar nursery, 17th August 2022

Poplar cabin, 23rd August 2022. Residues from cleaning up the modified silicon filler with methylated spirits have become evident after exposure to sunlight.

Cabin's cladding beginning to silver off, 15th December 2022

Disclaimer: The opinions and information provided in this report have been provided in good faith and on the basis that every endeavour has been made to be accurate and not misleading and to exercise reasonable care, skill and judgement in providing such opinions and information. The Author and NZFFA will not be responsible if information is inaccurate or not up to date, nor will we be responsible if you use or rely on the information in any way.

Farm Forestry New Zealand

Farm Forestry New Zealand